.

Introduction

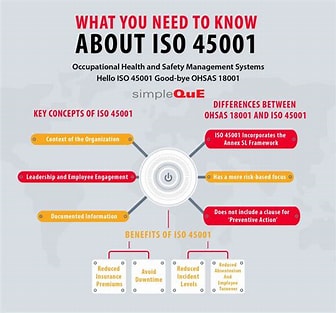

ISO 45001:2018 is a globally recognized standard for Occupational Health and Safety (OH&S) management systems. It provides a framework for organizations to improve employee safety, reduce workplace risks, and create safer working environments. This standard is designed to be adaptable across industries, ensuring that any organization, regardless of size or sector, can protect the health and safety of its workers.

Why ISO 45001 is Important

Workplace safety is a universal concern, and companies bear both moral and legal responsibility to ensure that their employees work in safe environments. ISO 45001 helps businesses achieve this by providing systematic processes to mitigate risks, prevent accidents, and comply with health and safety regulations. In addition to safeguarding employees, it also boosts productivity, reduces downtime due to incidents, and protects a company’s reputation.

Key Components of ISO 45001

ISO 45001 is built on the High-Level Structure (HLS), which aligns it with other standards like ISO 9001 (Quality Management) and ISO 14001 (Environmental Management). Below are the key clauses that make up the structure of the standard:

- Context of the Organization: This involves understanding the internal and external factors that affect the organization’s ability to manage OH&S. It requires identifying interested parties (e.g., employees, regulators, contractors) and their needs concerning health and safety.

- Leadership and Worker Participation: Leadership plays a pivotal role in establishing the OH&S system. Top management must demonstrate a commitment to safety, define responsibilities, and engage workers in safety initiatives.

- Planning: This clause focuses on identifying hazards and assessing risks. It requires organizations to create processes for risk management, opportunities for improvement, and emergency preparedness.

- Support: This involves providing resources, competence, training, and communication necessary to implement and maintain the OH&S system effectively. Documentation and proper record-keeping are also essential parts of this clause.

- Operation: This outlines the processes and procedures necessary to control risks in daily operations. It includes hazard identification, emergency preparedness, operational planning, and implementing control measures.

- Performance Evaluation: Organizations must monitor and evaluate the performance of their OH&S system. This includes regular audits, reviews, and assessing the effectiveness of risk management processes.

- Improvement: Continuous improvement is at the core of ISO 45001. Organizations are expected to regularly assess their OH&S performance and make necessary adjustments to prevent incidents, mitigate risks, and improve the safety culture.

Steps to Certification

Achieving ISO 45001 certification involves several stages, and organizations must commit time and resources to meet the standard’s requirements. Here’s a step-by-step overview of the certification process:

- Gap Analysis: Conduct a gap analysis to identify areas where your current OH&S system does not meet ISO 45001 requirements.

- Develop an Action Plan: Based on the gap analysis, create an implementation plan. This includes assigning roles, setting deadlines, and defining the necessary steps to meet the standard.

- Training and Awareness: Ensure that both management and employees understand their roles in the OH&S system and are trained in risk management and safety protocols.

- Documentation: Prepare the required documentation for your OH&S system, including policies, procedures, and risk assessments.

- Internal Audits: Before the formal certification audit, conduct internal audits to assess your organization’s readiness and identify areas for improvement.

- Certification Audit: Engage an accredited certification body to conduct the formal audit. This involves an on-site review of your OH&S system and processes to verify compliance with ISO 45001.

- Post-Certification Maintenance: After achieving certification, your organization must continually improve and maintain the system. This includes periodic audits and regular reviews to ensure ongoing compliance.

Conclusion

ISO 45001:2018 is a powerful tool that can significantly enhance your organization’s approach to occupational health and safety. By implementing this standard, companies can improve worker protection, meet regulatory requirements, and foster a culture of safety that boosts productivity and morale. The process of certification requires commitment, but the long-term benefits in terms of risk reduction, compliance, and overall safety are well worth the effort. A certified ISO 45001 system is not just a compliance measure—it’s a strategic asset for any forward-thinking organization.

Leave a Reply